The strain gauge signal will be conditioned and sampled at a maximum rate of up to 30 kHz, allowing 15 kHz bandwidth, with 24-bit equivalent resolution (using a 16-bit ADC with 256 x analogue pre-amplification of the strain gauge).

Analogue pre-amplification (gain) is to be specified by the customer, based on maximum expected bridge-level output. The system supports a full-bridge strain gauge of any resistance (eg 120 Ohm, 350 Ohm, 1 kOhm).

The transmitter accepts a Hall-effect Tacho sensor to provide a 1 PPR output, if required.

The supplied transceiver will offer analogue outputs (0-5 V) to be interfaced to a third-party acquisition unit.

A USB receiver, allowing streaming data to hard drive, is also available as a separate option.

It is advisable to use balancing resistors on the transmitter to perform balancing at bridge level before amplification and sampling. A multi-mode (dual colour) LED on the receiver indicates transmitter presence and gives health and warning indicators (such as low power).

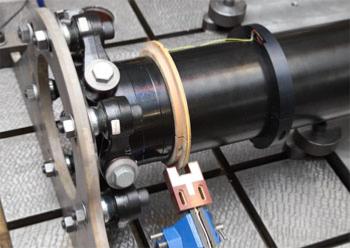

All rotating electronics parts are encapsulated to protect against mechanical shock and vibration (capable of withstanding 10,000 g mechanical shock acceleration). The system is designed to operate within the standard commercial temperature range of -20 to +85 °C.

If an inductive power supply is required, CAPTRONIC will design and manufacture a suitable inductive loop former to be mounted to the shaft.