|

|

The role of screws and nuts in mechanical assembliesDefinitions :

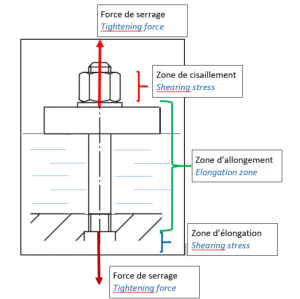

Screws, studs and nuts made of metallic materials are commonly used to assemble mechanical components. Although apparently "simple", the tightening of mechanical parts is very difficult to define and model finite element in its environment as a mechanical assembly component. Indeed, depending on the external loading conditions: elasticity, stiffness, combined resistance to shear-pulling. And the mechanical and thermo-mechanical stresses exerted on the assembled structures, it is necessary to choose the most probable configuration. by taking the "maximum" conditions of use.  Tightening monitoring by torque control (with torque wrenches) covers a large number of mechanical assembly cases in assembly procedures.

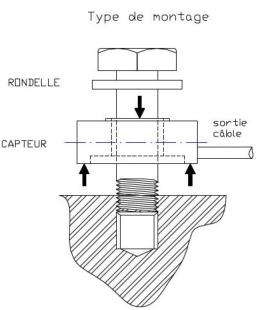

However, when the accuracy of the nominal value of the clamping force is required, control via a torque wrench is no longer suitable. To determine the tightening torque of a screw, charts are used giving the tightening torque according to the quality class or the fasteners resistance class, among the classes most used in mechanics: 8.8, 9.8, 10.9, 12.9 ... Example for a class 8.8 screw: Rr (mini) = 100 x 8 = 800 N / mm˛ Re (mini) = Rr x Y / 10 = 800 x 8/10 = 640 N / mm˛ Insertion of a force transducerWe insert a force sensor called: force washer or load washer with an internal diameter corresponding to the diameter of the screw. CAPTRONIC offers a range of force washers and manufactures custom-made sensors according to the requirements of metrological performance and dimensional characteristics.

Threaded fasteners: screws, studs, threaded rods are used in all sectors to assemble products ranging from pipes to earthmoving machines for industrial use, from cranes to bridges, etc. Their principle of operation is as follows: they create a clamping force exerted on the entire assembly which is able to withstand the conditions of use, without loosening. Properly tightened studs make use of their elastic properties: to be effective, they behave like very stiff springs. When a load is applied, the stud stretches and there is an equilibrium relationship that takes place: creep and relaxation which causes the clamping force to change over time after performing a tightening. This creates a compressive force through all of the components in the assembly. Advantage of this solution: simplicity and speed in the implementation. Among the drawbacks of this solution is the need for free space around the screw head to integrate the sensor. Then, it is mandatory to modify the tightening conditions using a longer screw length for mounting the sensor. On the right is a picture showing a model of force sensor that we design : load washer  On the right is a drawing showing a sectional view with integraton of our load washer CFR-070TX model of force sensor that we design : load washer

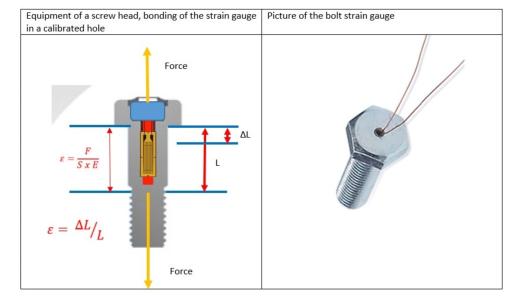

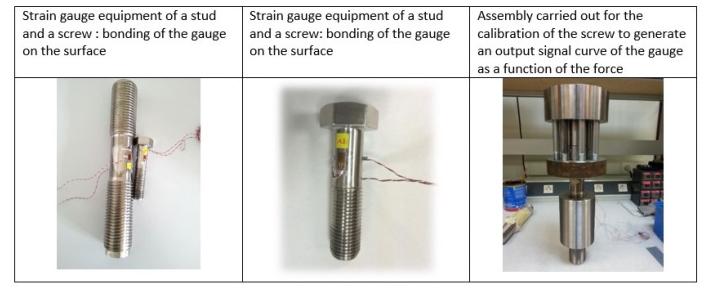

Bolt strain gauge : equipement of the screw upper part with strain gauge by drilling a hole in the screwIn the present case, the technical solution for measuring the clamping force is achieved by equipping the screw with a strain gauge stuck in a drilled hole, calibrated and located in the upper part located at the level of the screw head.  Compared to what was developed previously, the screw is fitted with a strain gauge by equipping the body of the upper part of the screw with 2 longitudinal gauges. The deformation laws are identical according to the applied force, the section of the shank of the screw and the Young's modulus of the material.  |